Because of our expertise in the boiler industry, we’re passionate about sharing gas burners and steam boiler facts and information with you. Maybe you’re an industrial history buff, or perhaps you’re in the boiler industry yourself. Maybe you’re just interested in knowing more about the piece of machinery that helps to power so many other industries, from brewing to food production, to healthcare. Regardless, keep reading to find out more about the steam-powered boiler, and to find out about where to go for the best in boiler maintenance and expertise.

Early Steam Boilers

The origin of the boiler can be traced back to England in the 17th century, with the inception of the very simple kettle boiler. The kettle boiler was just water, heated over a fire, which was then converted into steam through the heat.

Jump forward to the late 19th century, and it is widely accepted that the first people to patent a boiler were George Babcock and Steven Wilcox. Later, these men founded the Babcock and Wilcox Company in New York, USA. The Babcock and Wilcox company’s main venture was manufacturing boilers that were fuelled by coal and fed by hand.

Later, one of O.C. Barber’s companies The Stirling Boiler Company started to make boilers, and eventually, the Stirling Boiler Company would merge with the Babcock and Wilcox Company. They would be one of the major steam boiler manufacturers of their time, with their product the H-type Stirling, which was able to produce 50,000 pounds of steam per hour.

Boilers in the Industrial Revolution and Beyond

Boilers were a big feature during the industrial revolution, which was a time of incredible change and progress in manufacturing processes. A major advancement in the industrial revolution was the steam engine which was powered by a boiler.

The reason the steam engine was such a big part of this period of time and was so important is because it allowed for more reliable transportation of people, goods, and materials. Take a look at this Wikipedia page on steam engines to find out more about how boilers contributed to transportation at the time.

Further, in the period that followed the industrial revolution steam-powered boilers were prevalent during World War 1 and World War 2, in the form of steam-powered ships and boats.

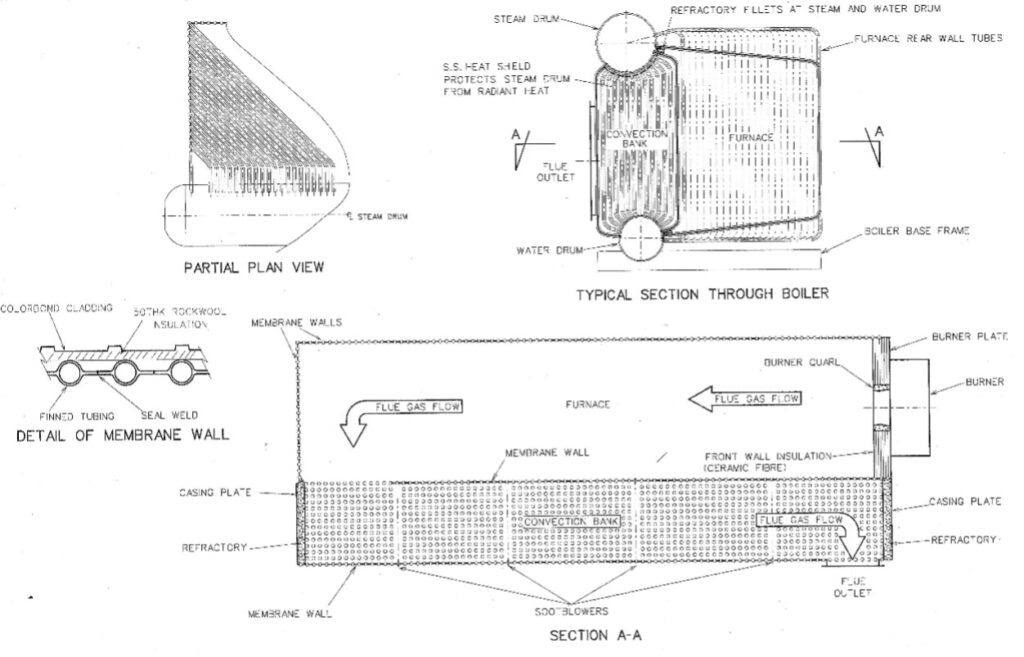

The Major Components of Steam Boilers

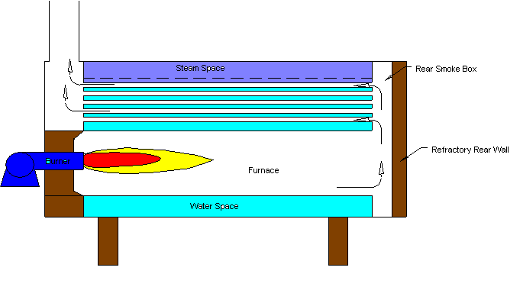

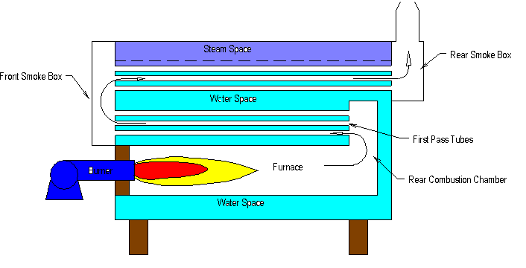

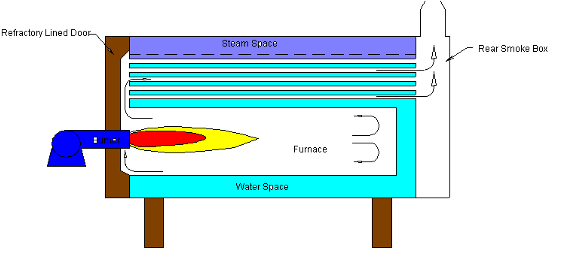

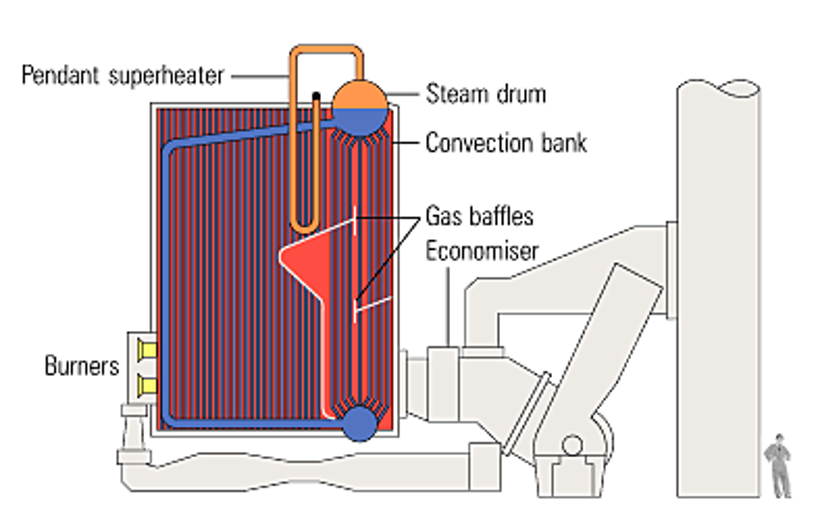

The Burner: The burner is the component of the boiler system where the fuel source, (whether that is oil, or coal, for example), meets the air and combusts.

The Combustion Chamber: This is a chamber that is traditionally made from cast iron, and its purpose is to burn the fuel inside in order to heat the water. The reason this is made from cast iron, or otherwise steel, is that the material needs to be able to withstand extreme temperatures – up to several hundred degrees!

The Heat Exchanger: The heat exchanger does what the name suggests: it transfers the heat that has been produced in the combustion chamber to the water. They are mostly made of stainless steel, as this material does not rust, and will not corrode.

Bonus Component: The Safety Valve

In general, a safety valve is a particular type of valve that acts as a fail-safe in a piece of machinery or equipment. This means that it’s a feature that will respond to a failure in the machinery in a way that will prevent or minimise harm to any people, or to the environment around the machine.

This makes the safety valve an incredibly important device. First developed and put into use during the industrial revolution, now they either come with a spring mechanism, balanced bellows or are pilot operated.

In steam boilers, the safety valve acts to relieve excess pressure that is in the boiler. This happens by the safety valve opening to release an amount of fluid from within the boiler once a particular amount of excess pressure is achieved. It can be catastrophic if the boiler reaches a level of pressure beyond the safe level, and if there is no safety valve to relieve this pressure. Check out our guide to these pressure valves to find out more about their importance to boilers.

Do You Need Boiler Maintenance Experts?

That’s what you’ll find at Tomlinson Energy Service. Backed by more than 100 years of engineering and service experience, we pride ourselves on providing exceptional customer service, as well as professional expertise in maintaining, repairing, and installing steam-powered boilers. Plus, as a member of the Environmental Group Limited (EGL), here at Tomlinson Energy Service, we are committed to sustainability and the protection of the environment.

When you need boiler maintenance or boiler repair, make sure to call us at your state-specific telephone number, or fill out our online contact form, and one of our industry experts will get back to you.