Steam Boilers – What Are The Main Types?

Boilers are a type of heating system that can be used to generate high-pressure steam-based energy. There are a variety of different types of steam boilers available, categorised by factors such as size, portability, how they function and more. What they all have in common is their use of fuel, to heat up hot water or generate steam. A common categorisation of boilers into ‘fire’ and ‘water’ boilers. This distinction refers to the design and heating features of the boilers.

A Short History of Boilers

Early steam generators were little more than kettles heated with a fire underneath. These were referred to as shell boilers and became common in the 17th century, almost 2000 years after Hero’s the novelty machine, called an aelopile, (alo-op-illy), or rotary steam engine was invented. The concept of steam being used to do useful work developed until, in the early 1600’s, Brance, an Italian engineer developed the first workable steam turbine. From this point on the demand for higher pressure and higher temperature steam increased.

In 1740 John Allen realised that the way to increase boiler efficiency was to increase the contact time between the hot gas and the heating surface and he developed a shell boiler with a smoke flue winding back and forth through the shell. He also conceived the idea of a bellows in order to force air through the boiler and thus overcome the problem of oxygen depletion in the furnace, probably the forerunner of the modern forced draft fan. Then In 1804 Richard Trevithick designed a simple fire tube boiler with a cast iron shell and dished ends and this became the basis for further development resulting in the modern multi-pass fire tube boiler of today.

Engineers, even during the early stages of the development of the fire tube design, were considering other possibilities. Williams Blakey’s basic water tube steam generator, (1766) was the predecessor of the early water tube boiler and as the requirement for higher pressure steam boilers increased, engineers recognised that the shell boiler had limitations and the real development of the water tube boiler began. The first truly successful water tube design came in 1856 when Stephen Wilcox developed his boiler with improved water circulation and increased heating surface. This boiler was inherently safe and development continued rapidly, culminating in the highly complex modern water tube boiler that is capable of operating at high pressure and temperature.

Fire Tube Boilers

Fire tube boilers are sometimes referred to as shell boilers or drum boilers. The name is derived from the fact that; a), the hot combustion gases pass through the tubes and the medium to be heated passes around the tubes or, b), the heating surfaces are contained within a “Shell” as in a “Shell and Tube” heat exchanger or a “Drum”. The maximum output and pressure rating of a fire tube boiler is usually limited by the maximum furnace thickness allowed by the Code, (22mm), which limits the diameter and pressure. In addition, a large diameter drum, (big enough to contain a furnace and tube bundle for the required heating surface), would need a disproportionate drum metal thickness in order to achieve the strength required, thus leading to increased manufacturing costs and weight.

A simple shell boiler comprises a drum into which is fitted a furnace tube, (housing the burner or fuel stoker), a rear combustion chamber or turning chamber, a bank, (or multiple banks) of tubes, referred to as smoke tubes or convection tubes and one or more smoke boxes or turning chambers. The tubes may be expanded or welded into the end plates of the shell, (the tube sheets), and there will be some heavy walled tubes called stay tubes and some solid bars called stay bars connecting the front and rear tube sheets. These are welded into the tube sheets and provide structural strength to the boiler. The boiler water is controlled at a level just covering the heated components, which allows some space for the collection of the steam. Various components are fitted to the drum to control the flow of feed water and steam and to protect against overpressure.

1 Wet and Dry Back Boilers

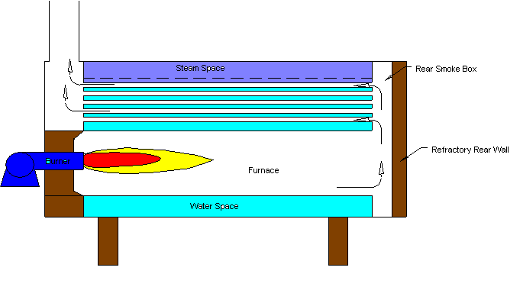

Shell boilers may be wet or dry back, (Fig 1). A wet back boiler will have the rear combustion chamber water cooled thus increasing the heat exchange surface and eliminating the need for refractory to protect the rear outer casing of the boiler from excessive heat.

2 Multi Pass Boilers

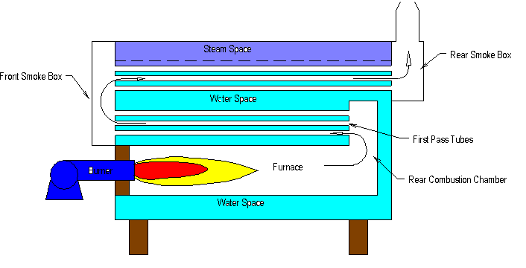

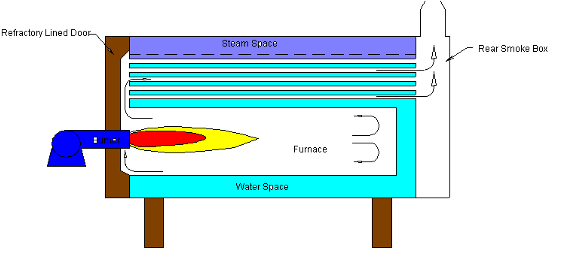

Modern boilers are generally two or three pass (Fig.2), i.e. the combustion gas will pass through the furnace, (first, pass) and a number of tube banks, (the second and third passes), before exiting through the stack. Some types, referred to as Reverse Flame or Return Flame (Fig.3), have a furnace that is closed at one end, which forces the combustion gas to return upon itself before passing through a tube bank and exiting via the flue.

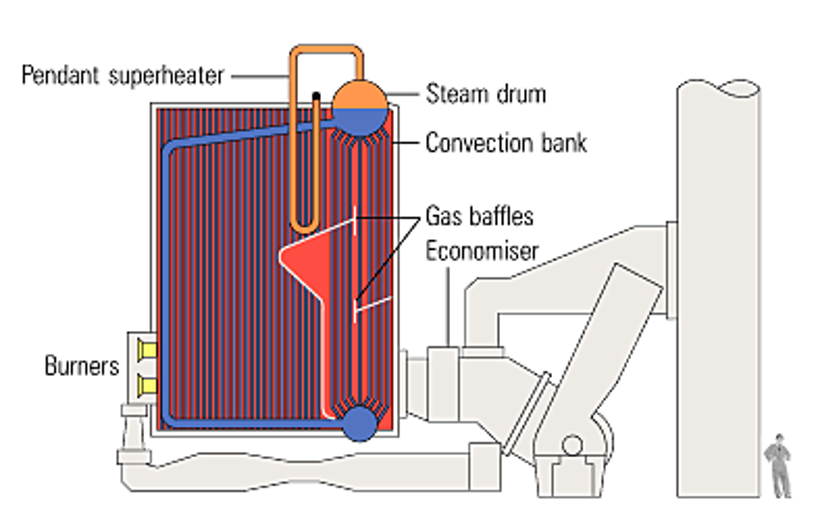

Water Tube Boilers

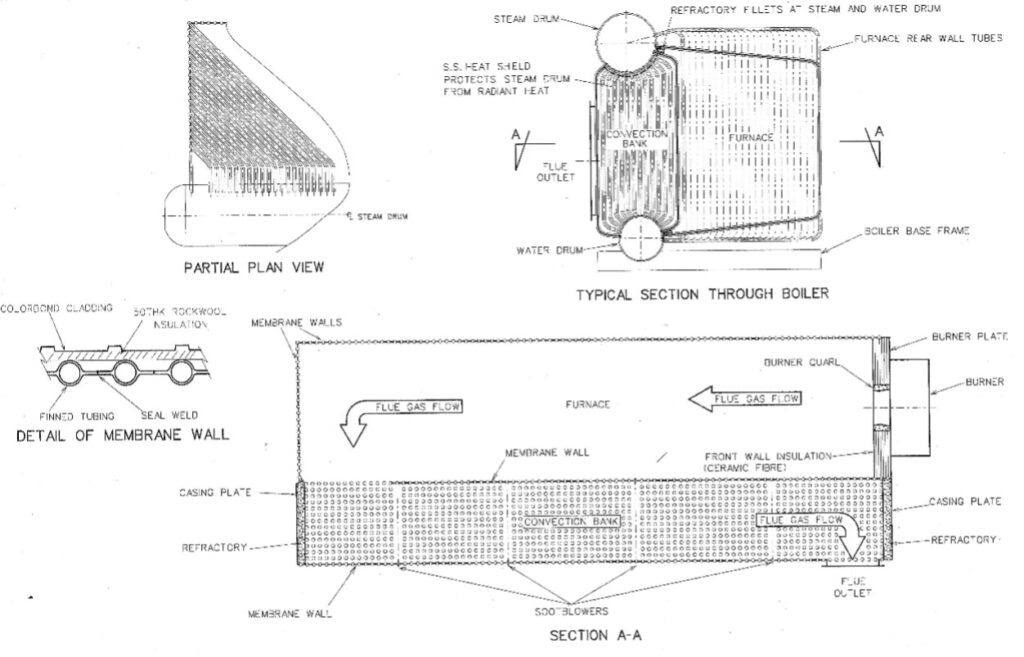

Water tube boilers (Fig. 4 and 5) are so called because the water passes through the tubes and the hot combustion gas passes around the tubes. Generally, a water tube boiler will have one or more drums into which the tubes are terminated. The configuration of the boiler will vary between types and manufacturers but generally, TES service technicians will be involved with bi-drum boilers such as the SD and SDGL designs or the Tomlinson “O” Type In these types the bottom drum acts as a reservoir for storing a reserve of water and the top drum a separation point for the steam and water factions and as a vessel in which the level of water in the boiler can be controlled. Other configurations include “A” types in which two bottom drums are connected to a single top drum and single drum types in which the tubes themselves form the storage component of the boiler. Circulation may be natural or forced and is an important facet of the design of the boiler.

Because the pressure parts are relatively small in diameter a water tube boiler is able to operate at a much higher pressure than a shell boiler. Water tube boilers may be gas, liquid or solid fuel fired. Such fuels as coal, wood waste, bagasse, black liquor, sludge, industrial waste, municipal waste or a combination of different fuel types can be used and may produce up to 4,500 tonnes of steam/hr at up to 310 bar and 590oC.

Tomlinson Energy has been one of the leading names within the Australian steam boiler industry for over a century. Boilers are an integral part of many businesses, so if you need help with installation, repair, or maintenance, get in contact to find out how we can support your business. Or check out our range of fire and water tube steam boiler products available today. With over a century of industry experience, Tomlinson Energy is a company you can count on to provide top-tier boiler services.

Get in contact with us at Tomlinson Energy Service via our contact form or call us at +61 3 8560 0419 to ensure smooth steam water boiler service and repair.

Quality and Performance

Tomlinson Energy Service NSW, VIC and SA have a dedicated management system with a focus on Quality, Safety and Environmental aspects of all our operations.

Accredited to ISO 45001:2018, ISO 14001:2015 and ISO 9001:2015.

Enquire Now

To request a no obligation quotation or make a general enquiry, please fill out the form below and one of our friendly staff will be in touch as soon as possible.